Structural Steel

Steel is an alloy of iron (Fe) with low carbon content (C) and manganese (Mn), in addition with small amounts of sulfur (S), phosphorus (P), silicon (Si) and oxygen (O) and is one of the most significant industrial materials. In the construction sector mild steel is found whose carbon content is very small and does not exceed 0.3% of its total weight.

Usage – Forms

Steel as a construction material is known to be used for decades to reinforce concrete. However, its high performance combined with the rapid development of processing technology and industrialization, have made steel the best choice in steel load bearing structures.

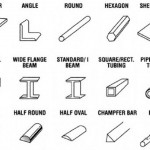

Structural steel results from hot rolled semi-finished steel products (circular or square cross-sections) at temperatures exceeding 900°C. Found in long (flat sheets, hollow sections, steel sections) products and flat products (metal sheets).They are formed in several profiles with specific geometric characteristics, which define their mechanical properties. The usual forms are I-sections, hollow sections (rectangular, circular), angles, U-sections, flat bars, square and round bars, etc.

A number of different systems classify sections depending on its geometry and size. In Cyprus, as in the rest of Europe, the European sections (HEA, HEB, IPE, etc.) are widely used, although sections according to the British standards (UB, UC, etc) are also used yet on a lower scale. America, Russia and Japan follow their own standards.

The type of a structural steel product, apart from its shape (e.g. IPE300, RHS100x100x6.3), is determined also by its quality (grade). This figure classifies steel depending on its composition and physical properties. In this case, there are again several international organisations which have established their own standards. We can come across among others the British BS4360 and German DN17100 standard nonetheless the European EN10025 tends to be adopted across Europe. Typical steel grade based on European standards include the most common S275JR and S355JR, where the numbers 275 and 355 respectively indicate the yield strength in N/mm2.

Comparison with other building materials

From a scientific point of view, steel has a number of different advantages in relation to other building materials like concrete and wood. For example:

- A relatively large region of plastic deformation exists in the stress-strain diagram. Practically this means that steel is sufficiently flexible to withstand loads beyond its yield point until final failure.

- It is the most environmentally friendly material, since it is 100% recyclable. In France, 40% of steel production results from recycling, saving about 60% of the energy required to produce it from raw materials.

- Compared to concrete, it is already at its full load capacity and does not require time to “cure”.

- Compared to wood, steel does not deform, neither distorts and it is in fact more resistant to temperature changes and generally to extreme environmental conditions.

- It has exceptional and essentially constant mechanical properties, as well as higher strength to weight ratio, which ensures the design of lighter constructions.